Olivier, working as a test engineer for the IT division of ALTEN, is crazy about slot racing: these miniature car races on huge tracks. Much more technical than we might think, Olivier, Scalex European champion in 2005, tells us in detail about his passion.

On a 57 meters long track, 8 miniature cars (per track) start, side by side, in different races: national and international 24-hours endurance, individual sprint of 4 minutes per track with cars of different categories (GT3/GTE, Group 5), interclubs, etc. In an endurance race, the cars are remotely controlled by a team of 4 or 5 people who take turns, the cars must be fast while avoiding going off the track.

How did you get here?

“I think that many children of my generation, when they were kids, received a circuit by Saint Nicolas on which they had a car and could, with the help of a joystick, go at full speed, make loops, turns and races with their brother or father. Well, I was one of them…

Being quite influenced by my dad, I quickly became a fan of cars and mechanics. Looking for a related activity, I went with my dad to a remote-controlled car club where I came across a poster for a 24-hour Scalextric race that we went to. It was in 1997, I was 13 years old, and I remember it like it was yesterday: there were two tracks, Italians, Spaniards guys… And right away it was…wow!

Not far from my home there was a shop (Freezslot), which was the sponsor of the race. The owner, Willy, was repairing fridges, but in his back shop there were thousands of car pieces. After school I would come by and I was like: “hello Willy, show me everything you have”. Then I finally started to buy a car, two cars, three cars to drive around in my cellar on my roller coaster. Then, 20 years ago, I discovered the Brussel Scalex Club and joined it. From my very first races I was quickly up in the rankings. “

At that time, you bought your cars, nowadays are you building them yourself?

“You have to know that they used to be really toys without any possible adjustments. If it is always possible to buy and drive with similar toys, there is now a very complete range of cars made for competition. Today, if you look at the car below (first picture from the left), which may seem banal to you, it is in fact a replica of a Ford GT, which raced at Le Mans in 2016. It was made in 3D printing. If you look more closely, there is the engine (21000rpm for this engine), the cradle (on which is fixed the engine, the rear axle, the transmission and the suspension), the chassis (in plastic with carbon wire), the rims (in magnesium) and the axles (in titanium), which makes it possible to adjust front axle, rear axle and suspension (these are only 3 examples of the dozens of possible adjustments), so it has nothing to do with toys anymore.Today, it is possible to buy kits, sold in shops. I have a replica of a BMW M6 in the GTE category (second picture from the left) on which I’ve just grafted pieces. You can change the chassis, with a softer or harder chassis, put in suspensions, change the engine, but also the rims or the transmission. All this, adjustable according to the type of circuit and your driving style.

At home, I have a small workshop where all my cars are (don’t ask me to count them, it would take me until tomorrow…). After each race, I dismantle and clean my cars there. Before each race, I prepare my cars there. I first learned how to prepare the cars from the club’s alumni, then I learned on my own, tried things that didn’t work, asked advice from those who knew, spent one or two hours on the track, driving, improving, feeling, adapting. It’s all about feeling. Today, as soon as I receive a car there are about ten things I do as a basic, because I know that these ten things will work. “

How long does a car last?

“After a 24-hour race, the car becomes symbolic especially if you won with it, so I tend to put it in a cupboard. But for example, this 911 Porsche (third picture from the left), it is three years old and has participated in many championships. There are parts that I replace because of wear and tear. In fact, during an endurance race we change tyres 4 to 6 times. To lose as little time as possible, we have created techniques to remove worn tires and put new tires back on with 3D tools. As in a real race, it’s all a question of time.

Two years ago, the headlight of our car broke during a crash in a straight line, knowing that during the night there is no light on the circuit, it was problematic. The globe of the headlight got lodged in the front rim, immobilising the car. We had to dismantle the car and change some parts, which took us 3-4 minutes of our time while the others continued their laps. This cost us the victory…”

You were telling me about driving style, can you tell me more about it?

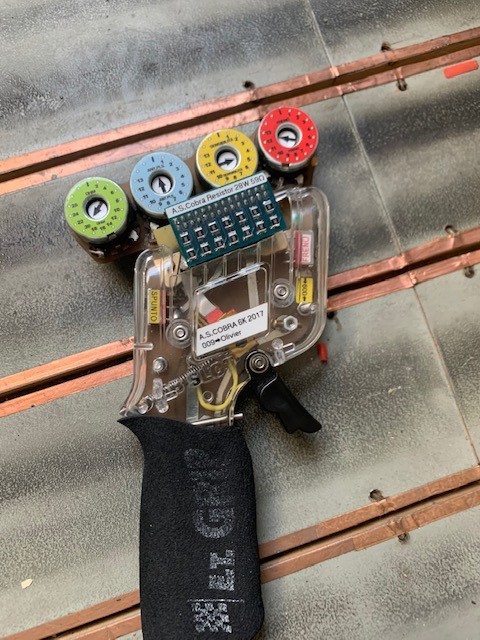

“Before talking about driving style, you must first understand the joystick. With our controller, we will be able to take control of the brakes, sensitivity, traction control and resistance. I don’t like to use traction control I don’t like the style, the feeling it gives to the driver.

For example, in Spain, the tracks are different from ours, the grain of the track is not the same, in Belgium we ride on English style tracks (Scalextric Sport brand). So, I choose one of my four controllers depending on where I go. “

What about the championships?

“My team and I have been driving together for 6 years. We have travelled several times to England, France, Italy, Spain and of course Belgium for 24-hour races. We always leave a few days before, giving us time for track tests and final adjustments. For 30 years our club has also organised the most famous race in Europe: the 24h of Joli-Bois. We won it many times (me 3 times, some of my teammates 5 times!). As an individual, I participate mainly in races organized within my club (where I have won almost every competition for the last 5 years) but also at the European level. In fact, I was European champion in 2005!

These races require a lot of practice, so I’ll train once or twice a week to keep up to speed and get my cars ready for the local championships. As soon as the 2021 championship starts again, I will be a member of a new team and this as an official trainer. I will have 5 cars to prepare per race … but I’ve been doing it willingly for several years for many members. Some of them are good drivers but don’t have the experience, the talent or the desire to start tuning.”

To conclude…

“For ALTEN I work as a Test Engineer in a food company, during my lunch break I often work on cars. My colleagues, seeing me with pieces from everywhere, asked me what I was doing. One evening I took them to Willy’s, who has his shop (Freezslot) and a track, which I was telling you about earlier. We have done racing car and we had a lot of fun all evening. It’s still a race, it’s fun! I have organized and participated in many team buildings (official or not) around slot tracks, it has always been a great success! Everybody can benefit from it!

Don’t hesitate, you too, to come to the club to see, if you’re a big kid you’re going to love it! “

Of course, Olivier closed this interview by thanking his teammates Fred, François and Fabrice! Many thanks Olivier for sharing your amazing activity!

You can find all the information about slot racing on the club’s website: Brussels Scalex Club as well as videos to learn more about these 24-hour races!

Are you interested in working at ALTEN? Please check our vacancies here.